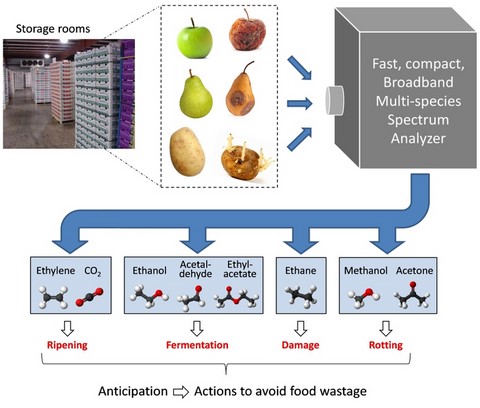

Fingerprint the quality of your fruits and vegetables

Senseair’s task in MAX-FRESH is to develop a multi-pass optical absorption cell with a 30 meter optical pathlength for the monitoring of the gas species associated with the deterioration of fresh produce of fruit and vegetables in storage facilities.

The new multi-pass cell is a key component in the ISS Monitor, where it is integrated with a supercontinuum laser source and a mid-infrared spectrometer. In addition to the very long optical path, the multi-pass cell features a controlled internal environment at low pressure, where air samples are injected by a gas handling system. Senseair also aims at making the multi-pass cell suitable for high-volume production by developing specific mirror and production technologies.

Read more on http://www.max-fresh.eu

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 958840.